- Air-conditioning

- Hot air freezing & drying system

- Air compressor system

- Ventilation & cooling system

- Electric lighting system

- Water pump & drainage system

- Construction of plastic welding field (plastic tanks, waterproof tarpaulins & biogas tunnels)

Air-conditioning

We provide consulting solutions, designing systems of air-conditioning and ventilation for buildings, hotels, luxury villas, cinemas, supermarkets, hospitals, factories, … suitable for performance and usage performance.

The solutions include technical consultation, giving overall design plans, choosing the product line suitable to the size of the project, the purpose and use of the investor to ensure efficient use. highest, from which a preliminary estimate for the system is made.

Air-conditioning system that we consult and design:

- Central air conditioning system VRV / VRF of Daikin, Mitsubishi, Panasonic, Toshiba, Samsung, LG,…

- Chiller air-conditioning system cooled by water and wind from Trane, Daikin, Carrier, …

- Cassette type air conditioner, Concealed, …

- Ventilation and air conditioning systems for civil and industrial projects.

Hot air freezing & drying system

The principle of freezing

Products are placed in aluminum trays with lids and placed on heat exchanger plates of contact freezers. Heat exchange takes place directly from the product through the tray to the heat exchanger plates. Thanks to the hydraulic cylinder system, it is possible to adjust the heat exchanger plates to have good contact with the two sides of the product. Simultaneous heat transfer occurs on both sides of the tray, resulting in short freezing times.

Exceptional Features

- Suitable for frozen seafood and food in block or semi IQF form.

- Designed and manufactured in accordance with HACCP / FDA standards.

- Fast, effective freezing and product quality assurance.

- The cabinet surface is made of stainless steel.

- Insulated with 150mm thick Polyurethane foam, density 43kg / m³.

- Hydraulic cylinder system lifts high quality heat exchangers. Ensures easy entry and exit as well as even contact between the heat exchanger plates and the freezer trays.

- Extruded aluminum heat exchanger panels are specialized in food processing technology.

- Using gas R 404, R502 or new types of gas.

- Operation, cleaning as well as maintenance are very easy and simple.

Specifications

- Insulate the freezer room with a 125 mm thick assembled PU panel, inside and outside the tolt color bond coating.

- The floor of the room has a slope towards the middle drain, which is convenient for spraying water to clean and defrost the indoor unit. The freezer door has enough size for workers to access and maintain and sanitize equipment.

- The actuator has an automatic tape tensioning mechanism which is able to avoid the tape being too stretchy or too loose due to the temperature elasticity of the tape.

- The conveyor support frame is lined with plastic bars, ensuring limited sliding friction with the conveyor, operating in high efficiency and having a long service life and meeting food hygiene requirements.

- The airflow distribution system is properly arranged, the distance of the blow slots is far enough that the two airways are not affected by friction and it is easy to create a COANDA effect on the product surface. This means that the efficiency of cold transfer from the air to the product is optimal, with a short freezing time and reduced product loss.

- Hinge-style windshields facilitate opening and closing each cleaning shift.

- Squirrel cage type indoor fan creates high wind pressure, stainless steel and dynamically balanced propeller, the suction line of the fan has a curved profile for the highest efficiency and energy saving, the type capable of operating in Deep cold environment and watering outside.

- Hot-dip galvanized steel tubes and wings with radiator fins of the indoor unit are sparse enough to last 16 hours or more. New commune rock.

Coming to Dai An is to the most prestigious industrial cold storage installation unit in Vietnam. Our projects can be found in all provinces. In addition to installing industrial cold storage, we also provide indoor units, cold storage machine clusters. For details, please contact 0913.731.688 for more information and receive cold storage quotes.

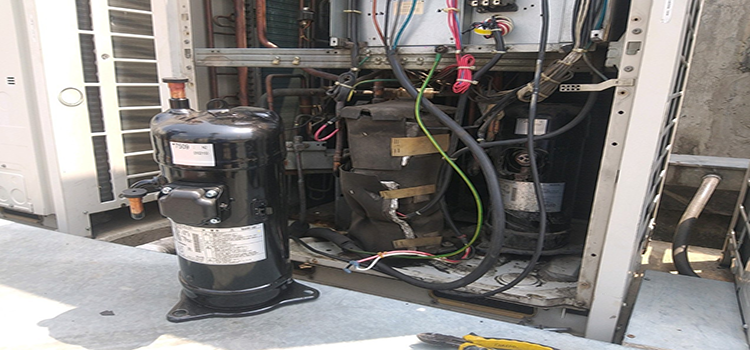

Air compressor system

Almost today, many businesses in different fields have to use compressed air for production. A complete compressed air system is not only a compressor, but also has a lot of auxiliary equipment to process the air after compressing it from the compressor. However, in fact, many businesses face many difficulties in choosing the type of air compressor, air dryer as well as designing the compressed air system to suit the needs.

Our compressor system design – consulting service will help you solve the problem of choosing the right and efficient compressed air system for your production model. from multiple devices and each one is irreplaceable. Components of the pneumatic system:

- Compressor

- Accummultor

- Air dryer

- Air filter.

With our experience in many compressed air system projects, we understand very well how a compressor room is designed to meet the standards of a well-ventilated, soundproof, and easy to use compressor room. easy to install as well as perform maintenance work in the future.

VWith this service you will be examined by us on the current facility; evaluating, measuring and analyzing with advanced technology equipment, in order to offer the most suitable solutions for you.

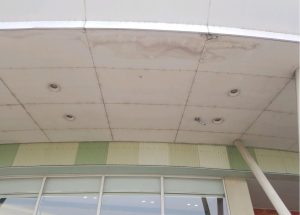

Ventilation & cooling system

Our unit, in addition to the strength of the field is the package construction of air-conditioning system; We also conduct technical consulting services for the ventilation system. Our unit consists of a team of experienced engineers, who have experienced key projects, so we can consult with customers to come up with optimal solutions for control systems. ventilation.

A ventilation system is a system that helps fresh air circulate in a confined space or space and to remove contaminated air. It is used in a variety of settings, including in the home and workplace. This system has many uses including maintaining constant humidity and temperature, removing air dust and allergens, supplying and exchanging O2 and CO2 gases.

The consulting scope includes the systems:

– Industrial cooling – ventilation solutions.

– Solution of dust extraction, waste gas treatment of industrial production processes.

– Solution to smoke the corridor, increase the pressure of stairs, and ventilate the basement for high buildings.

– High aesthetic air-ventilation solution for public buildings such as hotels, restaurants, etc.

– Smoke-absorbing solution of table-baking systems, smoke-free hot pot. Consultation content includes

– Calculate the cold load. Selection of refrigeration system technology. Choice of type – type of air conditioner. Calculate the parameters of auxiliary systems of air conditioners such as drainage pipes, control systems …

– Ventilation calculation. Select ventilation technology. Calculate the size of wind pipes, air valves, and air outlets.

– Design of auxiliary systems of ventilation systems. Select fan type, fan capacity, fan pressure …

– Optimizing the ventilation system: in addition to pure calculations, with a wealth of experience, we apply to consulting to optimize between initial investment costs, transportation costs. warranty – maintenance and system life.

Electric lighting system

For businesses that have factories, factories and warehouses, the investment and installation of appropriate lighting systems is an important issue. This not only helps to cut energy costs but also creates a comfortable, safe, and productive working environment.

In the design and construction of lighting electrical buildings, the most important issue to consider is to meet the requirements of illuminance and the effectiveness of lighting for vision. In addition to the illuminance, the effectiveness of lighting also depends on the luminous flux, the color of the light, the reasonable choice of the lampshade, the lighting arrangement while ensuring the technical economy and the aesthetic of the situation.

1. Requirements in design and construction of lighting system for factories.

- Be sure to illuminate the work area to the illuminance on the work surface. Also ensure the color rendering index of the lamp. Meet Vietnamese standard TCVN 7114-1: 2008.

- Meet power density and use energy most efficiently. Meet QCVN 09: 2013 / BXD National technical standards.

- Lighting equipment must be safe, economical and friendly with the environment. Products with high performance, guaranteed quality suitable for many spaces. The device must ensure lighting even in harsh environments.

- Use products with a wide temperature range. Ensure true reflection of the color of the object illuminated by the light.

- Illuminated space must absolutely limit glare. In some working objects, the reflected rays are also quite strong and direct, so when arranging the lamps, pay attention to avoid this phenomenon.

- Create the right light direction, not obscured.

- Reduce the number of maintenance and repair times, affecting production.

Just based on the lighting design criteria in the standard factory lighting, customers will get the light design ideas for their lighting spaces.

2. Choose the right light for factory lighting

Depending on the nature and requirements of the job and factory characteristics, the following lamps can be selected:

| HIGHBAY LIGHTS | MULTI-FUNCTIONAL LIGHT | HEADLIGH | LED LONG |

|  |  |  |

| Suitable for workshops with a lot of dust (such as wood industry), storage. | Suitable for work that requires high color temperature and color rendering | Suitable for factories with harsh environments. | Suitable for painting, garment, electronics room |

3. Lighting design unit for the factory

If you are in need of designing and constructing electric lighting for the factory, please contact us. DAI AN Technical Service & Trading Company specializes in designing and installing factory lighting systems, high voltage lighting systems, office lighting, street lighting, electric lighting bright residential area …. We hope to bring the knowledge and skills of our staff to serve our customers in the best way.

Water pump & drainage system

Construction of plastic welding field

Waterproofing membrane – The HDPE waterproof membrane or the HDPE waterproof sheet is made up of HDPE resin to create a membrane used for waterproofing civil and industrial projects. The waterproof membrane is used for thermal power projects, waste projects, shrimp farms, biogas tanks, salt mining pools and other applications.

- Extrusion welding machine

- Plastic canvas welding machine

- Welding machine

Good resistance to the impact of the environment, inert against chemicals, even to strong acids. Not affected by fungi, bacteria, termites. Resistant to aging by weather and climate effects.

With a team of experienced technicians, complete machinery and equipment for construction and installation, tarpaulin materials, DAI AN Trading & Technical Services Company will bring absolute satisfaction to customers.

Request Service Today!

We always innovate and improve the working environment, train and upgrade expertise and professionalism to maximize creativity & ability of the staff, in order to bring the best service solutions for customers.